Pipe Chain Conveyor

- Easy to realize centralized control and improve the level of automation. The centralized control function of the pipe chain conveyor is convenient for the management of the production line by factory managers and reduces manual operation errors.

- Compact structure, small space occupation, can change the conveying direction in three dimensions, not affected by terrain, angle and height; the conveying process is carried out in a closed pipeline, so the material is free from pollution and no dust is raised. This compact and closed design of the pipe chain conveyor is suitable for factories with limited space and high environmental protection requirements.

- The conveying process is smooth, there is basically no internal movement between materials, less damage, ensuring material quality, and suitable for abrasive materials. For manufacturers who need to ensure the integrity of materials, the pipe chain conveyor is an excellent choice.

- For the conveying of mixed materials, there will be no material stratification. This feature of the pipe chain conveyor ensures the uniformity of mixed materials, which is crucial for the production of products that require stable material composition.

- Large conveying capacity, low energy consumption, greatly reducing the equipment operation cost. The high efficiency and energy-saving advantages of the pipe chain conveyor help manufacturers reduce production costs and improve economic benefits.

- No system blockage, suitable for conveying materials of various forms. This avoids the production line shutdown caused by blockage, ensuring the continuous operation of the production line for production line engineers.

- Can realize long-distance conveying. The long-distance conveying capability of the pipe chain conveyor meets the material transportation needs of large-scale factories.

- Multiple inlet and outlet ports can be deployed at will to meet the process requirements. This flexible inlet and outlet design of the pipe chain conveyor adapts to different production process layouts.

- All moving parts operate in a closed space, which is safe and reliable. The safe operation feature of the pipe chain conveyor ensures the safety of the production site and protects the personal safety of employees.

Overview

Pipe chain conveyor is a continuous conveying equipment used for transporting bulk materials such as powder, small granular and small lumpy materials. It is a high-efficiency and energy-saving conveying solution widely applied in various industrial fields.This equipment features flexible layout, high conveying efficiency, reliability and durability, low maintenance rate and long service life, making it an ideal energy-saving and environmental-friendly conveying equipment for short and medium distances. It is generally used in fine chemical industry, pesticide and mineral industry, construction materials industry, food industry and other fields. Pipe chain conveyor is the first choice for many manufacturers to optimize material conveying processes.

Pipe chain conveyor is also called powder pipe chain conveyor, pipeline chain conveyor, circular pipe conveyor, pipe chain conveying equipment, etc. It is a continuous conveying equipment for bulk materials like powder, small granular and small lumpy materials, and can realize horizontal, inclined and vertical combined conveying. It meets the diverse conveying needs of production lines in different industries.It consists of a closed pipeline, with a driving device and a tensioning device at the end of the pipeline, and an inlet and outlet on the conveying pipeline. The closed structure of the pipe chain conveyor ensures no material leakage during the conveying process.Driven by the driving device of the transmission mechanism, the conveying chain moves circularly along the inner wall of the conveying pipeline to the feed inlet, thus completing the pipeline conveying of materials. This working mode ensures stable and efficient material transportation for the pipe chain conveyor.The entire conveying process of the pipe chain conveyor is carried out in a closed manner inside the pipeline. This closed operation effectively prevents dust from flying and material pollution, which is in line with the environmental protection requirements of modern factories.This equipment has the characteristics of flexible layout, high conveying efficiency, reliability and durability, low maintenance rate and long service life. It has become an ideal energy-saving and environmental-friendly conveying equipment for short and medium distances, and is generally used in fine chemical industry, pesticide and mineral industry, construction materials industry, food industry and so on. For manufacturers and procurement personnel in these industries, the pipe chain conveyor is a cost-effective conveying equipment option.

Pipe chain conveyor adopts pure mechanical principle, and uses the circular movement of chain and scraper inside the pipeline to drive the material movement, which can completely ignore the problem of material fluidity. This design makes the pipe chain conveyor suitable for conveying materials with poor fluidity, solving the conveying difficulties of many production line engineers.In terms of layout flexibility and conveying distance, the pipe chain conveyor can change angles freely. Whether it is vertical lifting, horizontal conveying, or complex Z-type, S-type and circular conveying, it can well undertake the conveying task. This flexible layout ability makes the pipe chain conveyor adapt to different factory spaces and production line layouts.In addition, the pipe chain conveyor adopts the external bearing method to isolate the power device from the materials, and cooperates with the fully closed pipeline to achieve dust-free and pollution-free conveying. This feature is particularly important for the food and pharmaceutical industries that have strict requirements on material hygiene.

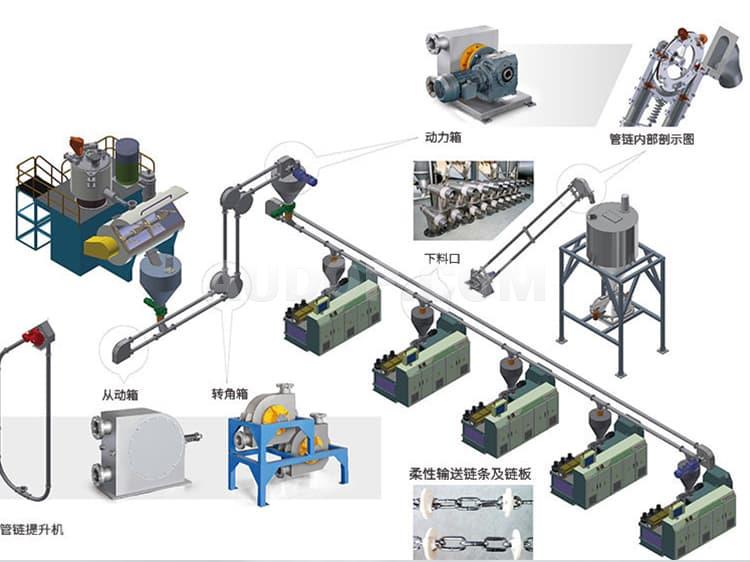

Components:

- Pipe chain conveyor is usually composed of driving machine, tensioning machine, steering machine, conveying pipe, conveying chain and control system. Each component of the pipe chain conveyor is designed to ensure the stable operation of the entire equipment.

- Driving Machine: Composed of motor, reducer, sprocket, driving shaft, bearing and driving machine box. The high-quality motor and reducer of the pipe chain conveyor ensure strong power output and stable operation.The driving machine box is divided into three categories: ordinary type, closed type and high-temperature type according to the working site conditions. The high-temperature type box is equipped with a bearing cooling system. This classification allows the pipe chain conveyor to adapt to different working environments, meeting the needs of various industrial scenarios.

- Tensioning Machine: Also known as tail box, the tensioning machine is composed of sprocket, driving shaft, bearing, tensioning mechanism and machine box. There are two tensioning methods: counterweight and spring, and vertical conveyors are not equipped with tensioning mechanisms. The reasonable tensioning design of the pipe chain conveyor ensures the normal operation of the conveying chain and reduces the failure rate.The tensioning machine box is divided into three categories: ordinary type, closed type and high-temperature type according to the working site conditions. The high-temperature type box is equipped with a bearing cooling system. This design ensures that the tensioning machine of the pipe chain conveyor can work normally in different environments.

- Steering Machine: A special device used to realize the three-dimensional conveying and turning of the pipe chain conveyor. The steering machine enables the pipe chain conveyor to change the conveying direction flexibly, enhancing the adaptability of the equipment to the production line.

- Conveying Pipe: Composed of straight pipes and elbows with a certain bending radius connected by flanges with a special structure. The high-strength conveying pipe of the pipe chain conveyor ensures no deformation during long-term use and guarantees the smooth conveying of materials.

- Conveying Chain: A closed circular chain composed of chains and chain plates. The wear-resistant conveying chain of the pipe chain conveyor has a long service life, reducing the maintenance cost for manufacturers.

- Control System: Composed of electrical components and PLC. The intelligent control system of the pipe chain conveyor is convenient for production line engineers to operate and realize centralized control, improving the automation level of the production line.

Working Principle:

Inside the closed pipeline, the chain plate is used as the transmission component to drive the material to move along the pipeline. This working principle of the pipe chain conveyor ensures the stability and efficiency of material conveying.During horizontal conveying, the material particles are subjected to the thrust of the chain plate in the movement direction. This thrust ensures that the materials move forward smoothly in the horizontal direction of the pipe chain conveyor.When the internal friction between the material layers is greater than the external friction between the material and the pipe wall, the material moves forward with the chain plate, forming a stable material flow. This is the key to the horizontal conveying of the pipe chain conveyor, ensuring no material accumulation.During vertical conveying, the material particles in the pipe are subjected to the upward thrust of the chain plate. Since the lower feeding prevents the upper material from sliding down, a horizontal lateral pressure is generated, thus enhancing the internal friction of the material. This design of the pipe chain conveyor solves the problem of material sliding during vertical conveying.When the internal friction between the materials is greater than the external friction between the material and the inner wall of the pipe and the self-weight of the material, the material is conveyed upward with the chain plate, forming a continuous material flow. This ensures the continuous and stable vertical conveying of the pipe chain conveyor.Powder materials move linearly along the closed pipeline in three-dimensional space, with right-angle turns or Z-type conveying, and the direction can be changed if necessary. This multi-directional conveying capability of the pipe chain conveyor meets the complex material conveying needs of different production lines.

Advantages:

- Good Sealing Performance: The entire system operates in a closed pipeline, with no leakage and no dust. Gas can be filled to provide gas protection for the conveyed materials, avoiding environmental dust pollution. The good sealing performance of the pipe chain conveyor is in line with the environmental protection policies of modern enterprises and is favored by factory managers.

- Energy Saving: There is point contact between the conveying chain plate and the conveying pipeline, with small friction and low power consumption. The energy-saving advantage of the pipe chain conveyor reduces the energy cost of enterprises, which is an important consideration for procurement personnel when choosing conveying equipment.

- Three-Dimensional Conveying: Combined conveying methods such as horizontal, inclined, vertical and turning. The three-dimensional conveying capability of the pipe chain conveyor makes it possible to optimize the production line layout, saving factory space.

- Volumetric Conveying: Materials will not be squeezed, ensuring the integrity of materials. For materials that are easily damaged, the volumetric conveying of the pipe chain conveyor is an ideal choice, ensuring the quality of the final products.

- Simple Structure: The driving machine box and the driven machine box have simple structures, low failure rate, convenient operation, long service life and low maintenance rate. The simple structure of the pipe chain conveyor reduces the maintenance difficulty for production line engineers and lowers the maintenance cost of enterprises.

Application Fields:

- Petrochemical and Plastic Industry: PP, PC, PVC, PS, PA, PET, ABS, PTA, EVA, etc. In the petrochemical and plastic industry, the pipe chain conveyor is widely used for the conveying of various raw materials, improving the production efficiency of the industry.

- Chemical Industry: Calcium carbonate, sodium carbonate, sodium hydroxide, dolomite, titanium dioxide, barium sulfate, zinc oxide, starch, kaolin, talc, fatty acid, stabilizers (lead, zinc), alumina, emery, glass frit, lime, sand, clay, dry soft mud, polyester, resin, solvent, kiln drop products, titanium dioxide, etc. The pipe chain conveyor can meet the conveying needs of various chemical materials, and its closed structure prevents chemical material leakage and ensures production safety.

- Rubber Industry: Polymers, carbon black, silicon, precipitated silicon, white fillers, trace components, rubber compounds, etc. The pipe chain conveyor helps the rubber industry realize the efficient and clean conveying of raw materials, promoting the development of the rubber industry.

- Plastic Industry: Petrochemical raw materials, filler calcium carbonate, kaolin, chalk, stabilized artificial rubber lead, calcium, zinc, tin, processing aid pigments, titanium oxide, lubricants, plasticizers DOP, DIDP, ESO, plastic particles, etc. The pipe chain conveyor is an important equipment in the plastic industry's production line, ensuring the smooth progress of the plastic production process.

- Food and Pharmaceutical Industry: Rice-based food, rice flour, flour, coarse flour, wheat bran, wheat flour, crystalline sugar, rock sugar, milk powder, starch, malt, glucose, cocoa beans, coffee beans, peanuts, black beans, vegetable oil, fat, citric acid, salt and additives, etc. The food-grade pipe chain conveyor meets the strict hygiene requirements of the food and pharmaceutical industry, ensuring the safety and quality of food and pharmaceutical products.

- Electric Power and Metallurgical Industry: Fly ash, desulfurization ash, dust removal ash, slag, copper powder, iron powder, aluminum powder, etc. The pipe chain conveyor is used for the conveying of solid waste and metal powders in the electric power and metallurgical industry, realizing the recycling and utilization of resources.

- Construction Materials Industry: Cement, sand, stone, fly ash, etc. In the construction materials industry, the pipe chain conveyor has high wear resistance, which can adapt to the conveying of abrasive materials such as cement and sand, and has a long service life.

Maintenance:

- Cleaning. Keep the inside and outside of the pipe chain conveyor clean (including mining machinery parts). Ensure that there is no oil stain on each sliding surface, lead screw, rack, gear box, oil hole, etc. No oil or air leakage at each part. Mechanical engineers should clean up the chips, debris and dirt around the equipment. Regular cleaning of the pipe chain conveyor is an important part of maintenance, which can extend the service life of the equipment.

- Tidiness. Place tools, accessories and workpieces (products) neatly, and arrange pipelines and lines in order. The neat arrangement of the pipe chain conveyor and its accessories is convenient for daily inspection and maintenance, and reduces the probability of faults caused by messy placement.

- Good Lubrication. Refuel or change oil regularly to ensure no oil shortage and no dry friction. Keep the oil pressure normal, the oil level gauge clear, the oil circuit unobstructed, and the oil quality meets the requirements of Tianjin machinery. Keep the oil cup and oil felt clean. Good lubrication of the pipe chain conveyor can reduce the wear of moving parts and ensure the stable operation of the equipment.

- Operating Procedures. Abide by the operating procedures, do not use the equipment beyond the load. Ensure that the protective devices of the equipment (including Liugong machinery parts) are complete and reliable, and eliminate potential safety hazards in a timely manner. Abiding by the operating procedures of the pipe chain conveyor is the key to ensuring the safe and stable operation of the equipment and protecting the safety of operators.

Technical Parameters

Technical Parameters

| Model | Transmitting Ability(m³/h) | Chain Wheel Rotational Speed(r/m) | Chain Plate Linear Speed(m/s) | Motor Power(kw) |

| GL80 | 4 | 20 | 0.29 | 4 |

| GL100 | 8 | 18 | 0.31 | 4.5 |

| GL130 | 10 | 16 | 0.31 | 5.5 |

| GL150 | 16 | 15 | 0.31 | 7.5 |

| GL200 | 28 | 12 | 0.3 | 11 |

| GL250 | 48 | 10 | 0.3 | 15 |

| GL300 | 60 | 8 | 0.28 | 18.5 |

| GL400 | 60 | 8 | 0.28 | 22 |

Your requirements are the basis for our development and a daily challenge to bring to fruition, please do not hesitate to inquiry us.

Spring Feeder

- Easy to install and movable. For example, if multiple mixers use the same material, only one spring feeder can supply materials to multiple mixers at the same time, eliminating the trouble of manual feeding and making the feeding work safer, more time-saving and labor-saving. This movable spring feeder effectively reduces the number of equipment purchases for enterprises.

- Reasonable design, easy operation and maintenance. Compared with vacuum feeders, this spring feeder eliminates the trouble of frequent filter cleaning, reducing the workload of equipment maintenance for production line engineers.

- Adopting advanced electrical control components and motors to ensure safe and reliable operation of the system. The spring feeder has a large conveying capacity, with a maximum feeding capacity of 3 tons per hour, meeting the material supply needs of large-scale production lines.

- Wide application range. This spring feeder can convey powder materials, plastic granular materials, powder-granule mixtures, and can also be used with crushers. It is also suitable for conveying powder and granular materials in the production processes of the pharmaceutical and chemical industries. This wide-application spring feeder is a versatile choice for different industrial scenarios.

- Low energy consumption. Compared with traditional vacuum feeders and spring-type dust feeders, the energy consumption of this spring feeder is only about one-third, helping enterprises reduce energy costs and achieve energy-saving production.

Turn Belt Conveyor

- Flexible adaptation: Supports multi-angle turning (30°, 45°, 90°, 180°), and the inner/outer radius, belt width and frame height can be customized according to needs to meet the layout of narrow spaces or complex assembly lines.

- Stable conveying: The conveyor belt runs stably, with no relative movement between materials and the conveyor belt, which can effectively avoid damage to conveyed items, and is especially suitable for production links with high requirements for material integrity.

- Low noise and energy saving: It has a low noise level, creating a quiet working environment for the workshop, and at the same time, it has low energy consumption, reducing the production and operation costs of enterprises.

- Durable and easy to maintain: It adopts standardized component design, with a simple structure and convenient daily maintenance; it has low energy consumption (power matched according to needs) and obvious advantages in long-term use cost.

- Diverse materials: The conveyor belt has a variety of materials, including PVC, PU, etc., and some can also meet special needs such as oil resistance, corrosion resistance and anti-static, adapting to different materials and working environments.

- Safe and efficient: The design without sharp corners ensures the safety of operators; it supports high-speed conveying (linear speed adjustable from 0 to 50 meters per minute) to meet the needs of large-flow material transmission.

FU Scraper Conveyor

- It is often used for horizontally conveying granular and powdery materials, and can also be used for inclined conveying within an angle range of 150°. The FU scraper conveyor is flexible in material conveying directions.

- It has the characteristics of long overall service life, stable operation, small structural size, large conveying capacity, low energy consumption and low material damage rate. These features make the FU scraper conveyor a cost - effective choice for factories.

- The overall structure is reasonable, allowing multi - point feeding. Driven by the reducer, the scraper moves stably at a low noise level. On the basis of single - point feeding and discharging, it can also realize multi - point feeding and discharging. It has outstanding advantages in conveying toxic, explosive, high - temperature and easy - to - fly materials, improving workers' operating conditions and reducing environmental pollution. The FU scraper conveyor is an excellent choice for environmentally friendly and safe material conveying in industries.

Folding Conveyor

- The folding belt conveyor has a relatively simple structure and is easy to install and maintain.

- The conveyor belt is generally made of rubber material, which has good impact resistance and can withstand a certain degree of impact force.

- The folding belt conveyor can be folded after work, with a small floor space. It is a very ideal material conveying equipment for places with limited space.

- It can replace manual material handling, reduce labor costs, convey materials continuously and has high work efficiency.

TD Bucket Elevator

- Small driving power, adopting inflow feeding and induced discharge.

- The dense arrangement of large-capacity hoppers ensures that there is almost no material return and digging during material lifting, so the ineffective power is low.

- It has a wide lifting range and has few requirements on the type and characteristics of materials. It can not only lift general powder and small granular materials, but also lift materials with high abrasiveness. It has good sealing performance and causes little environmental pollution.

- It operates reliably. Advanced design principles and processing methods ensure the reliable operation of the whole machine, with good trouble-free operation performance.

- It has a high lifting degree, and the elevator runs stably, so it can reach a relatively high lifting height.

- It has a long service life. The elevator adopts the inflow method for feeding, without the need to dig materials with hoppers, so there is little extrusion and collision between materials.During the design process, it is ensured that there is little material scattering during feeding and unloading, which reduces mechanical wear.

- It can lift all conventional materials. For ordinary rubber belts, the temperature shall not exceed 60?. If heat-resistant rubber belts are used, the temperature can reach 200?.